BT130 mechanical winch for remote control and resetting of Actuated Safety Devices (ASD) on vents. Manually operated by lever on the front or remotely via electromagnetic module (ref. 9602B) or pneumatic module (ref. 9603B), it facilitates the renovation of mechanical controls. NF-certified red metal cover; crank (ref. 9530) supplied.

| Product | Reference | Landmark | Designation | Price | Availability | Quantity |

|---|---|---|---|---|---|---|

|

9530

|

- |

Price

€17.50

HT

|

In stock

|

|

||

|

9602B

|

- |

In stock

|

||||

|

9603B

|

- |

In stock

|

||||

|

9607

|

- |

Price

€108.35

HT

|

In stock

|

|

||

|

9609

|

- |

In stock

|

||||

|

9613

|

- |

In stock

|

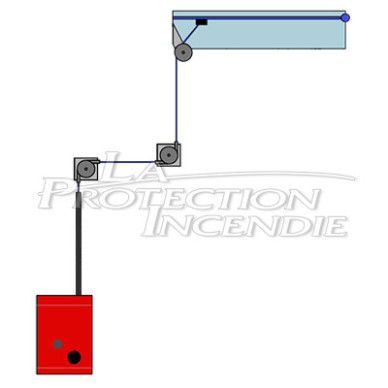

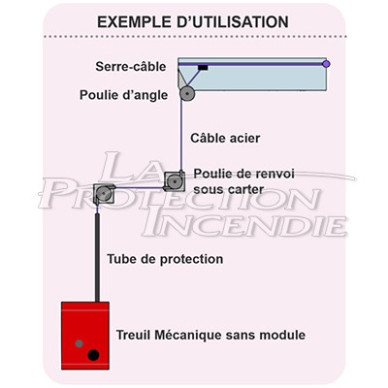

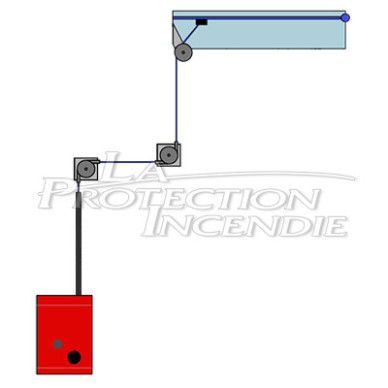

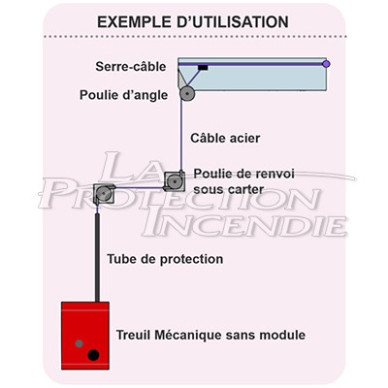

The BT130 mechanical winch is used to control the opening of vents (DENFC) and to ensure their safe return after triggering . It is designed to be operated manually , by lowering the lever on the front, or to be controlled remotely via an electromagnetic module (ref. 9602B) or pneumatic module (ref. 9603B).

In DAC configuration, manual action on the lever triggers the mechanism; in DCM/DAC configuration, opening can be controlled remotely via an electric or pneumatic remote control. The product is suitable for securing and resetting manually triggered servo-controlled devices , and it is integrated into mechanical remote control renovation operations.

The main winch block is fixed to the wall using four screws (max. diameter 7 mm); the casing can be removed and replaced once the block is fixed to facilitate installation. The fixing centers indicated are 150.5 mm in height and 81.50 mm in width.

The winch-outlet connection can reach 15 m if the cable route is fully visible , otherwise the recommended length is 8 m . The system accepts up to three pulleys maximum , each change of direction per pulley not exceeding 110° in relation to the cable route. A protective sheath is recommended up to 2.5 m from the ground.

In case of fire, lower the lever on the front for a DCM/DAC or control the winch by remote control line for a DAC.

After manual activation, re-arm the winch by positioning the crank (ref. 9530, supplied) on the hexagonal part, then tilt downwards; if it gets stuck, turn the crank slightly to the right or left until it engages.

After a pneumatic trigger, purge the circuit by removing the CO₂ cartridge then reset.

After an electrical trip, return the line to standby mode, remove the cover, replace the counterplate on the suction cup and reset according to the manual procedure.

During maintenance operations, grease the winch's "wheel and screw" assembly and clean the counterplate and suction cup if necessary using a suitable spray. Regularly check the mechanical condition and dirt, and provide the crank (ref. 9530) for resetting operations.

- Material: Steel

- Height: 182 mm

- Width: 110 mm

- Depth: 106 mm

- Weight: 3,110 Kg

- Force to be applied to the lever: 5 daN

- Traction force: 0.1 (Minimum) to 130 (Maximum) daN

- Endurance: 120 cycles (Minimum)

- Winding drum diameter: 38 mm

- Releasable cable: 4 m in 2.4 mm (Maximum)

- Cable diameter: up to 3.9 mm

- Additional accessories: electromagnetic module (ref. 9602B); pneumatic module (ref. 9603B); crank (ref. 9530 supplied)

- Functions: manual triggering by lever, electric or pneumatic remote control, mechanical reset with crank